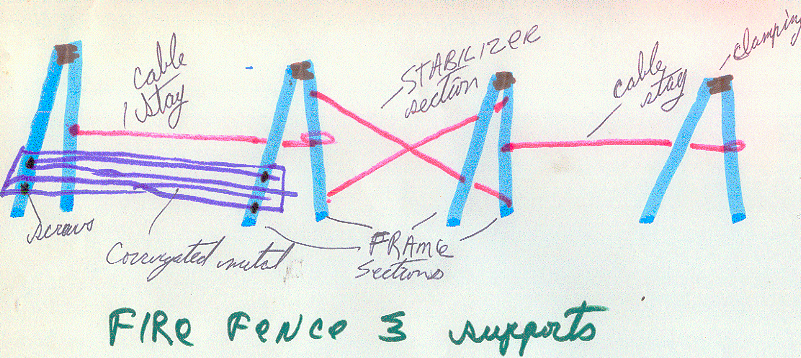

The simple machine/ includes an assembled A-FRAME, which can then be hooked together with cables. To form a fence. One stabilizing section includes a cross cabling to control sway/ followed or preceded by two sections with only one cable stay, for the cheapest solution.

The A-frames can be fixed or hinged, but includes pinning for cables. Corrugated sheet metal is then attached to the fire facing side with screws to stabilize it. What is actually needed depends entirely upon wind. Wood can be used for the A-frame, ONLY if you are using non- combustible spacers to give it at least 3 inches from the hot metal. ONLY if it is all sheet metal facing the fire, as ash will come through and potentially ignite the wood. A non-combustible area needs to be prepared in advance.

This method allows for frames to be distributed quickly, and set up. Followed by the sheet metal and crew to screw the entire fence together. Taller structures need wire on top, or the wind could blow it down. If these are prepared wire, then top and bottom are laced with piping. So as to simply hook the wire on top of the A-frame, and clamp the bottom wire piping, onto the corrugated metal quickly. If on prepared ground, anchoring should not be necessary.

IF, the wind is not considered a problem; regular steel fencing posts can be driven into the ground and corrugated metal wired to it. Once a non-combustible area has been established. Such as, by a small four foot wide tillage tool. A disk with blades that only focus dirt away from the center line, is probably best. When it is simply a field on fire/ tillage tools to crush the flammable substances should be/ are usually enough.